Offset vs Digital: What is Your Tipping Point

Most commercial printers have a hybrid print production using both offset and digital printing in their print manufacturing. What are some factors to consider in having a job print digital or offset? What factors should you consider in a new printing equipment investment?

FACT:

- Digital has a clear advantage in producing complex variable-data printing (VDP).

- Trillions of printed pages are produced worldwide each year using traditional offset press technology, so digital has really only replaced a small percent of the total work produced despite the keen industry focus on this technology.

- Many “hybrid” print service providers (PSPs), offering full-color digital output, report that 60% to 70% of their revenue dollars still comes from the offset print side of their businesses.

What is your tipping point?

The term “tipping point” is defined as “a time during a process when an important decision has to be made or when a situation changes completely”. When it comes to print production, print estimators and planners must decide whether a print job will be produced using an offset press or a digital press. The general rule of thumb has been, short run jobs print digital and longer run jobs print offset.

What qualifies as a short or a long print run?

Is the magic number 10,000 sheets or anything over 5,000? Has it come down to 2,000 or even 400 sheets? The answer, of course, depends on so many variables related to workflow, plates and makeready times. Newer offset press technology is more automated than ever.

Most ROI calculations made by digital press manufacturers attribute a long makeready time that does not relate to current offset press technology, so the deck often stacked in a way that ignores the changes that have occurred in offset during the same time that digital went from 60 CPM at $.25/sheet to 1,000s of CPM at a much lower cost. In other words, we sometimes treat offset print production like it’s been stuck in time, but that’s not the case.

FACT:

- Automatic plate loading, inline color bar cameras, and “smart” job loading allows for 6-minute makereadies and getting to color in less than 100 sheets.

- Commercial printers are seeing cost and production economies in print jobs as short as 400 sheets.

- LED curing means that even uncoated sheets are 100% dry immediately so post-press processes can begin without delay.

- 8UP+ offset presses are routinely staffed with a single pressman, and productivity and uptime more than rivals any digital platform.

The economics of Offset vs Digital Print

VS

One huge advantage for digital printing is of course the ability to produce variable-data printing. However, selling variable-data printing (VDP) as a capability is not the same as delivering a complete VDP project. Data dominates the personalized landscape, which makes the success of VDP projects a huge IT and database challenge for many PSPs because it is such a specialty niche. What often happens is that digital printers revert to selling static print jobs or offering “personalization” like postcard addressing on their digital presses at a much higher cost than offset printing and inkjet addressing.

Print firm owners and managers tend to base purchasing decisions on manufacturing economics, and some PSPs get locked into click-charge cost models on digital presses. Toner or inkjet on paper is always more expensive than modern LED offset: about 6-8 cents per sheet for digital versus 1-3 cents per sheet for properely produced offset sheets.

In addition to click charges, equipment acquisition costs need to be considered along with maintenance plans. Digital printing has much higher downtimes (both maintenance and break-fix) and, if used for high volumes, the machines take a beating. Between purchase/lease pricing, maintenance and click charges, the total cost of ownership can add up to $75,000 to $80,000 monthly to achieve the same results that a modern offset press can produce for less than half that amount. And a modern offset press will outlast any digital device by a factor of 3:1, at least.

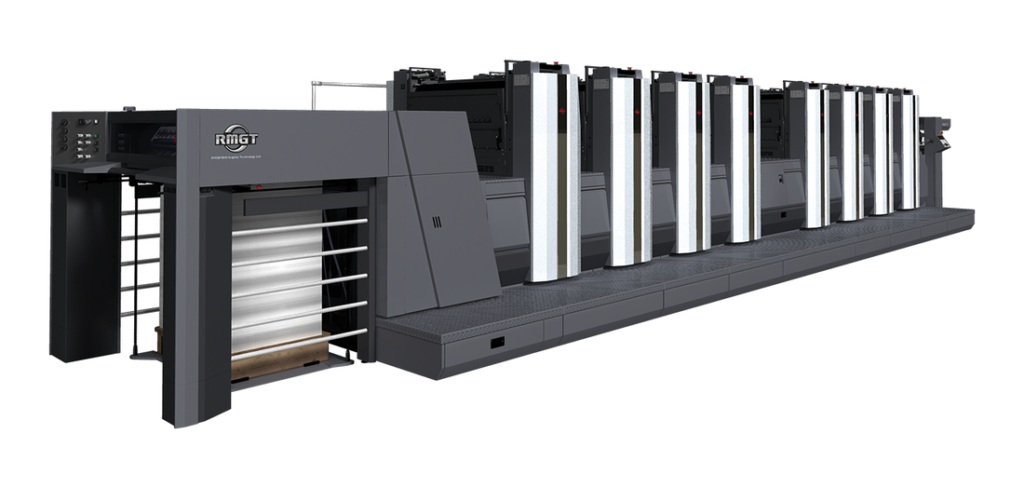

In the past eight years, RYOBI MHI Graphic Technology Ltd. (RMGT) has installed more than 100 sheetfed-offset presses at North American customer sites. It and other offset press manufacturers continue to invest in research and development to remain competitive:

- Their engineers squeeze precious minutes from make-readies, and waste sheets are a fraction of what they once were.

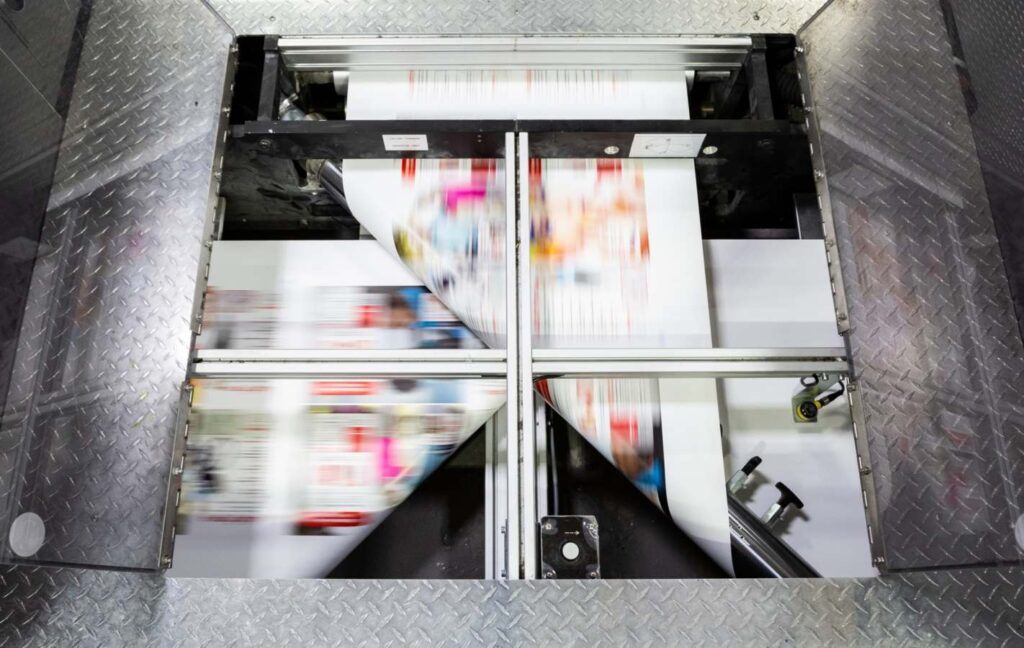

- Offset presses offer simultaneous changing of printing plates, wash-up blankets, scan/control color on each sheet and produce up to 240,000 sheets per hour (using 8.5 X 11” segments).

- Smart press consoles “learn” color adjustments, paper path optimization and provide cloud-based production reporting in real time.

- There have been recent major advancements in software and electronic vision enhancements as well, and much of this new technology brings offset print production cost advantages with an ease of use that even digital can’t touch.

RMGT’s 970 series models aare 8UP+, 25x38-inch format presses, with LED curing and feature Automated Smart Assist Printing (ASAP) with full camera systems. With the simple touch of a button, ASAP allows a press operator to autonomously manage the entire printing process — from ink and paper presetting, blanket and impression cleaning, and plate changing through verification of test printing, register adjustment, ink-density adjustment and full sheet inspection — without even pulling a sheet.

If you would like to learn more about how to evaluate your tipping point please reach out to us and we can begin a dialog on this topic.

RMGT “Open Mic” – “The Economics of Offset Printing vs. Digital Printing: Cockrell Enovation”