BRD Printing Adds 50th RMGT 9 Series Press Sold by Graphco: 8-UP+ Size 970 Press Landing in April

CLEVELAND, OH – March 20, 2024 – Graphco, a leading graphic-arts equipment dealer/distributor in the midwestern United States, next month will install a full-size RMGT 5-color 970 press at BRD Printing. The general commercial print firm employs more than 30 full-time employees who produce brochures, catalogs and magazines in a 28,000-square-foot plant (Lansing, MI), which operates two shifts daily. Capable of running 16,000 sheets per hour (sph), not only is the new, 38-inch machine almost twice as fast as the 1996 vintage model it is replacing, but it has all the modern automation “bells and whistles,” including LED-UV curing and a Harrison Bruno coater.

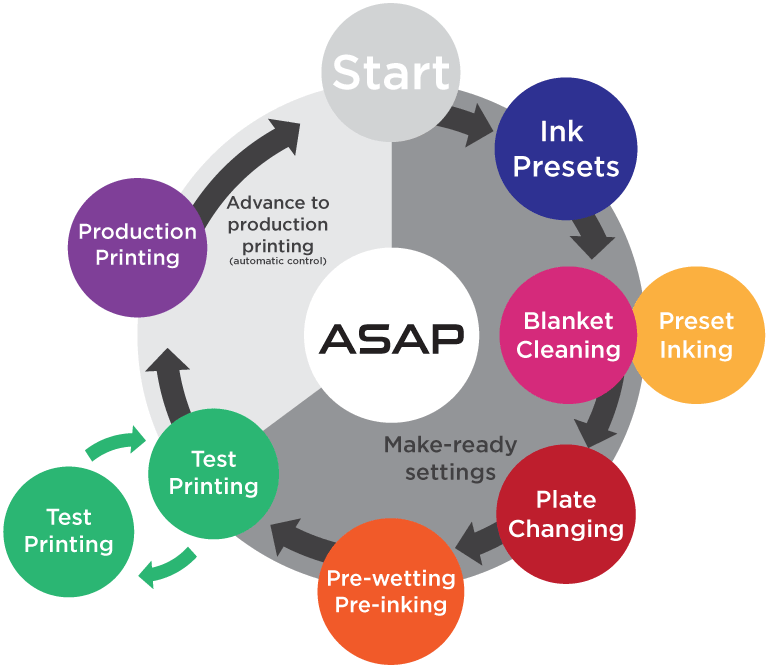

“Some 98% of what we do is standard, CMYK four-color process work,” explains Dave Lee, President, and CEO. With makereadies happening 75% quicker on the incoming RMGT press, Lee expects ROI (return on investment) to come back in a big way, fast. “We project to save $335,000 in paper and makeready efficiencies over the next twelve months. Our waste sheets should drop by 75%, maybe more,” he factors -- savings that will help to defray eroding profit margins amid persistent paper shortages.

“David was blown away by the amount of paper spoilage they had in a year’s time,” states Chris Manley, President of Graphco. “He was convinced that once his operators hung the four printing plates, there had to be a better, more efficient way to get up to color. We demonstrated that way with RMGT technology. He talked to owners and press operators who consistently reported make-ready waste reductions going from 1,000 sheets down to 200 or 300 sheets on runs of 10,000. Those numbers captured his attention.” The RMGT 970 Series accommodates a maximum paper width of 38 inches. Job volumes at BRD range widely from 500 sheets up to hundreds of thousands. One recent project consisted of printing and binding 1,500 copies of a 228-page book.

Lee is hopeful that the new, eight-up press can help to get BRD back to its pre-COVID financial performance. He has run the numbers. “We printed 53 million pieces in 2019,” he reports, which equates to more than 60,000 pages. “Our sales five years ago were over $6.5 million,” adds Lee, who first began sweeping the shop floor as a high-school teenager back in 1984. He then learned how to run presses and, nine years later, was named GM. Lee, now 57, bought out Don Hough, who founded BRD in 1977, when Hough retired in 2015.

Using MIS-generated numbers based on 2022 data, Lee projects an annual cost savings of $165,000 in paper waste alone. “That’s going to represent a lot of tonnage saved between now and next spring [2025],” he notes. Instead of needing 11,000 to 11,500 sheets for a 10,000-run job, BRD will need only 10,400 to 10,500. In a real-world example, one job last year consisted of printing fourteen 16-page signatures. “There were 800 sheets per form,” Lee relates, and BRD amassed 11,200 sheets of makeready waste. “On the new press, that number should be around 2,500 [waste] sheets. When you multiply that level of savings for every job, it adds up quickly,” he points out.

On top of that figure, he calculates saving an additional $170,000 or so on elapsed makeready times, which should compress down to 10-15 minutes from 45-60 minutes. “Even if we save only 30 minutes per makeready, the savings still are substantial,” Lee notes.

The BRD team also is excited about the ability to expand into new market areas with the help of the RMGT 970ST. “We anticipate that we’ll be more competitive on existing work and able to go after stuff we don’t get today, such as bigger catalog runs with longer page counts as well as board work and packaging,” Lee says. “Since our other press could only handle an 18-point board, we were turning away work. With the RMGT 9 Series, we can print on up to 24-point boards. We have a lot of work in that sweet spot between 20- to 22-point board.”

If you would like to be contacted with more information on how the RMGT 970 can benefit your business, please fill out the form.