Graphco Marks Milestone Year with Successful PRINTING United Expo Appearance

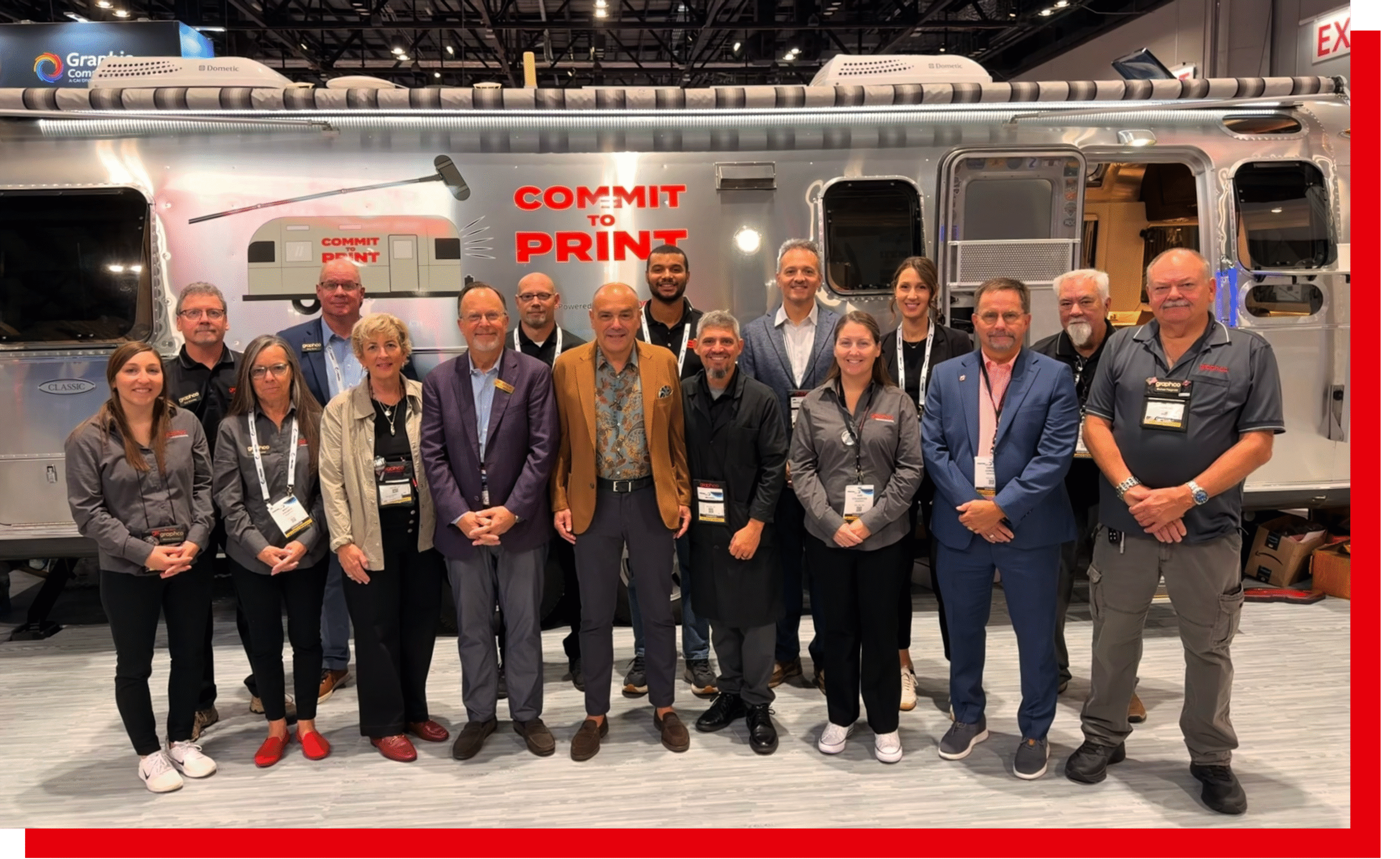

SOLON, OH — November 10, 2025 — Graphco, North America’s leading provider of offset presses, print finishing systems, and dimensional signage solutions, made a powerful impact at PRINTING United Expo 2025. The company strengthened dealer relationships, closed significant new business, and showcased live demonstrations of high-performance, production-driven technologies. Anchored by its signature Airstream trailer, the Graphco booth maintained a steady flow of attendees representing commercial, digital, packaging, and sign printing operations from across North America.

“PRINTING United 2025 exceeded our expectations,” said Chris Manley. “Buyers came prepared to invest — we closed five machines on the show floor and began negotiating several additional projects. Conversations focused on automation, expanded finishing capabilities and faster turnarounds, which signals concrete growth opportunities for our customers and for Graphco as we head into the new year.”

Throughout the event, visitors experienced hands-on demonstrations and detailed technical overviews from SD-Italy, RMGT, Foliant, and Fold Stream, while Graphco specialists guided attendees through complete, integrated workflows that unite offset, finishing, and dimensional fabrication.

SD-Italy Takes Center Stage

The Pinnacle Award–winning SD-Italy Augusta F150R Pro commanded attention as the booth’s headline attraction. Demonstrated live as a high-speed, production-grade CNC routing and cutting system, the Augusta F150R Pro emphasized its advanced Auto Stud Welding feature.

Live demos showcased how the system’s automated stud-welding head precisely attaches threaded studs and aluminum standoffs into substrates — enabling fast, repeatable hardware installation for dimensional signage and display assemblies. Attendees also witnessed precision routing, kiss cutting, and drag knife operations across a wide range of materials, including corrugated board, foam, acrylic, aluminum composite, and wood.

This solution proved ideal for sign shops, large-format providers, and fabricators producing POP displays, exhibits, architectural components, and complex dimensional signage.

Key Features Demonstrated:

- Automated multi-tool changer for rapid transitions between routing, cutting, and scoring

- Auto Stud Welding head for precise, repeatable hardware insertion with reduced manual assembly

- Zoned vacuum table for secure holding and efficient multi-part nesting

- Closed-loop servo control for sub-millimeter accuracy and consistent edge quality

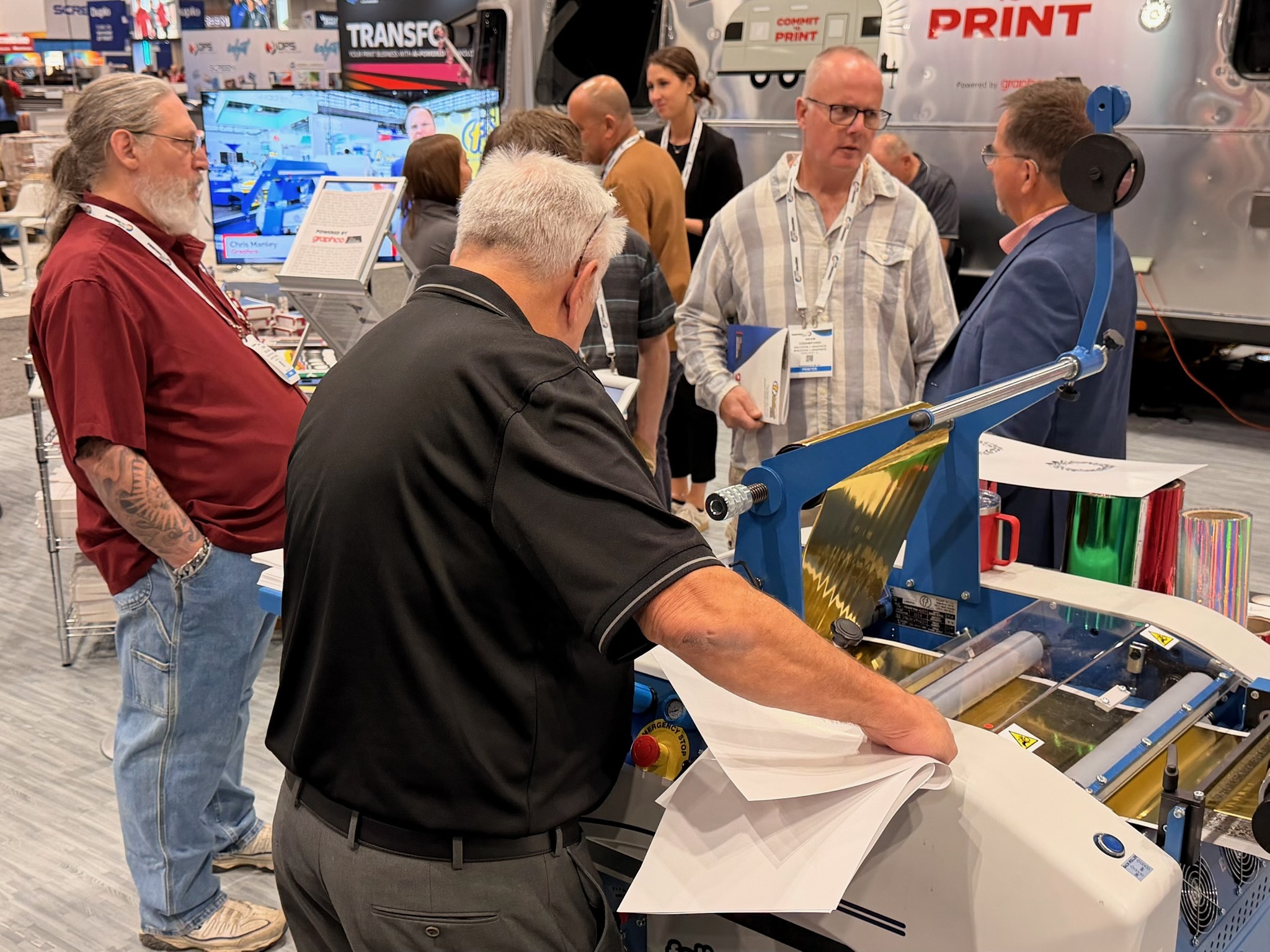

Foliant Showcases Laminating Innovation

Our Foliant Laminators drew strong attention with two standout systems – the Taurus 530NG 4x4 dual-sided laminator and the Vega 400A with foiling – both praised for their combination of speed, precision, and high-end finishing capabilities. “We were thrilled to debut these laminators at the expo,” said Manley.

The Taurus 530NG 4x4 demonstrated its ability to handle dual-sided lamination with exceptional gloss and matte finishes. Compact yet powerful, it delivers the versatility today’s print providers demand – from quick-turn digital jobs to high-volume offset runs.

Meanwhile, the Vega 400A drew crowds with live demonstrations of foiling, showcasing how easily printers can add shimmering metallic effects and embellishments to short-run projects. Attendees saw firsthand how the Vega’s foiling option enables quick setup, precise registration, and cost-effective decorative finishing — opening new opportunities for value-added print.

Foliant System Highlights:

- Heavy-duty, high-throughput laminator capable of dual-sided lamination on sheets up to 53", featuring advanced nip control and tension management for wrinkle-free, consistent gloss or matte finishes.

- Designed for short to mid-run production with increased line speed, quick changeovers, and robust construction for continuous operation in demanding environments.

- Integrated digital foiling capability on the Vega 400A, delivering eye-catching metallic finishes and special effects without the need for dies or complex setups

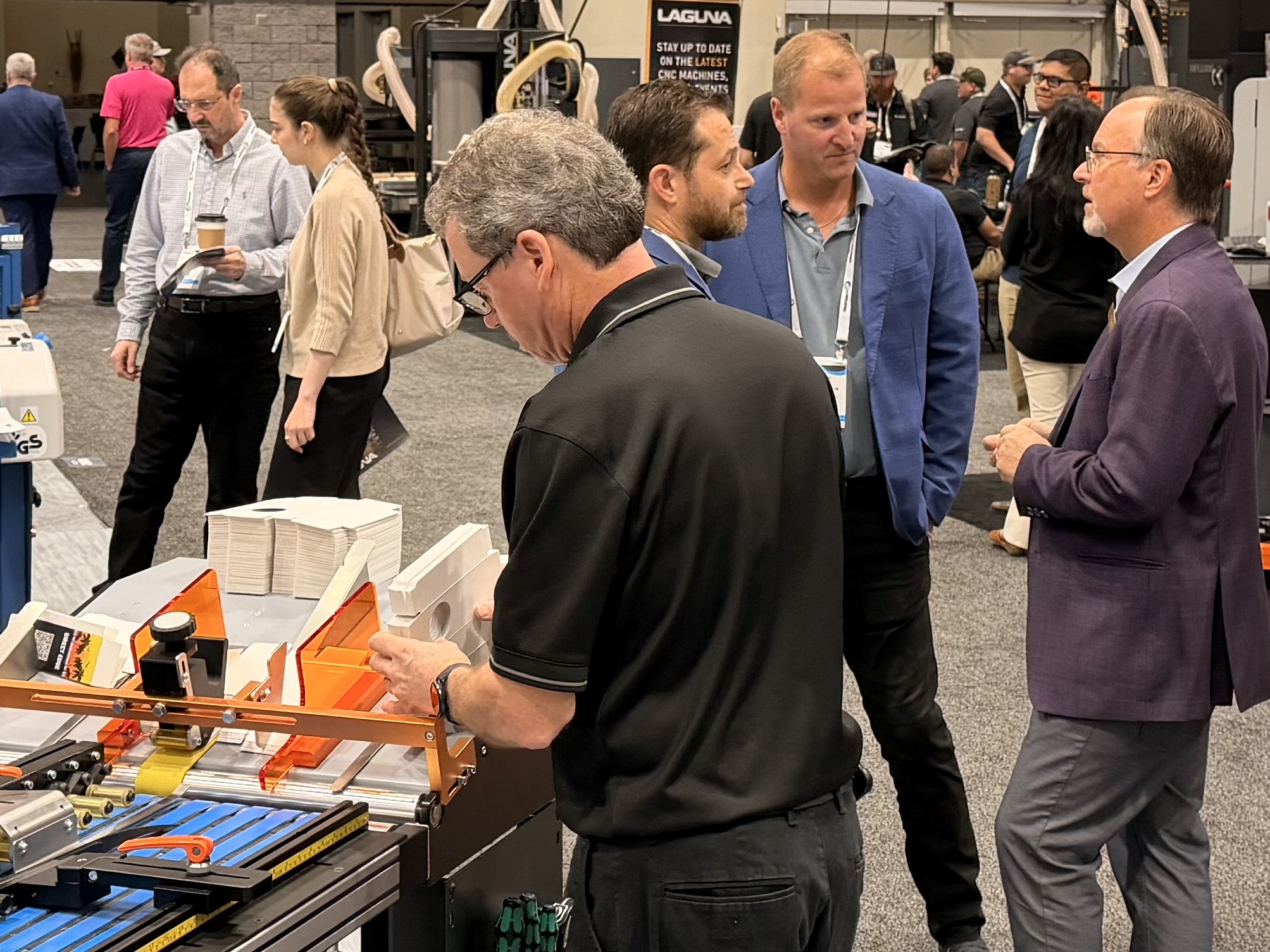

Fold Stream Draws Short-Run Packaging Printers

The Fold Stream attracted strong interest from packaging printers focused on short-run, on-demand production. Demonstrated live at the show, this compact, modular system showcased its ability to streamline folding, gluing, and inline finishing processes — all within a single, highly efficient platform.

Designed for versatility, the Fold Stream helps packaging operations reduce setup time, maintain consistent quality, and adapt quickly to a variety of box styles and configurations. Attendees saw the machine effortlessly handle a range of substrates while delivering precise, repeatable folds and accurate glue placement.

Fold Stream Highlights:

- Multi-belt drive eliminates belt changes between jobs, simplifying setup

- Guided tools with quick-release fasteners for fast, accurate positioning

- Adjustable spring-loaded drive rollers ensure uniform pressure for consistent folds and glue adhesion

- Independently adjustable plows (height and angle) for smooth flap turns and precise fold definition

- Interactive touchscreen controls to fine-tune speed, glue position, and glue length for repeatable, high-quality results

Strong Sales Signal Strong Momentum

“PRINTING United was an incredible success for Graphco. We connected with hundreds of shops actively investing in equipment to increase throughput, broaden capabilities and improve margins,” said Chris Manley, President of Graphco. “The energy in our booth translated directly into orders and new partnerships — a clear signal that the market is ready to accelerate.”

If you would like to learn more about anything you saw at the show, fill out the following form.