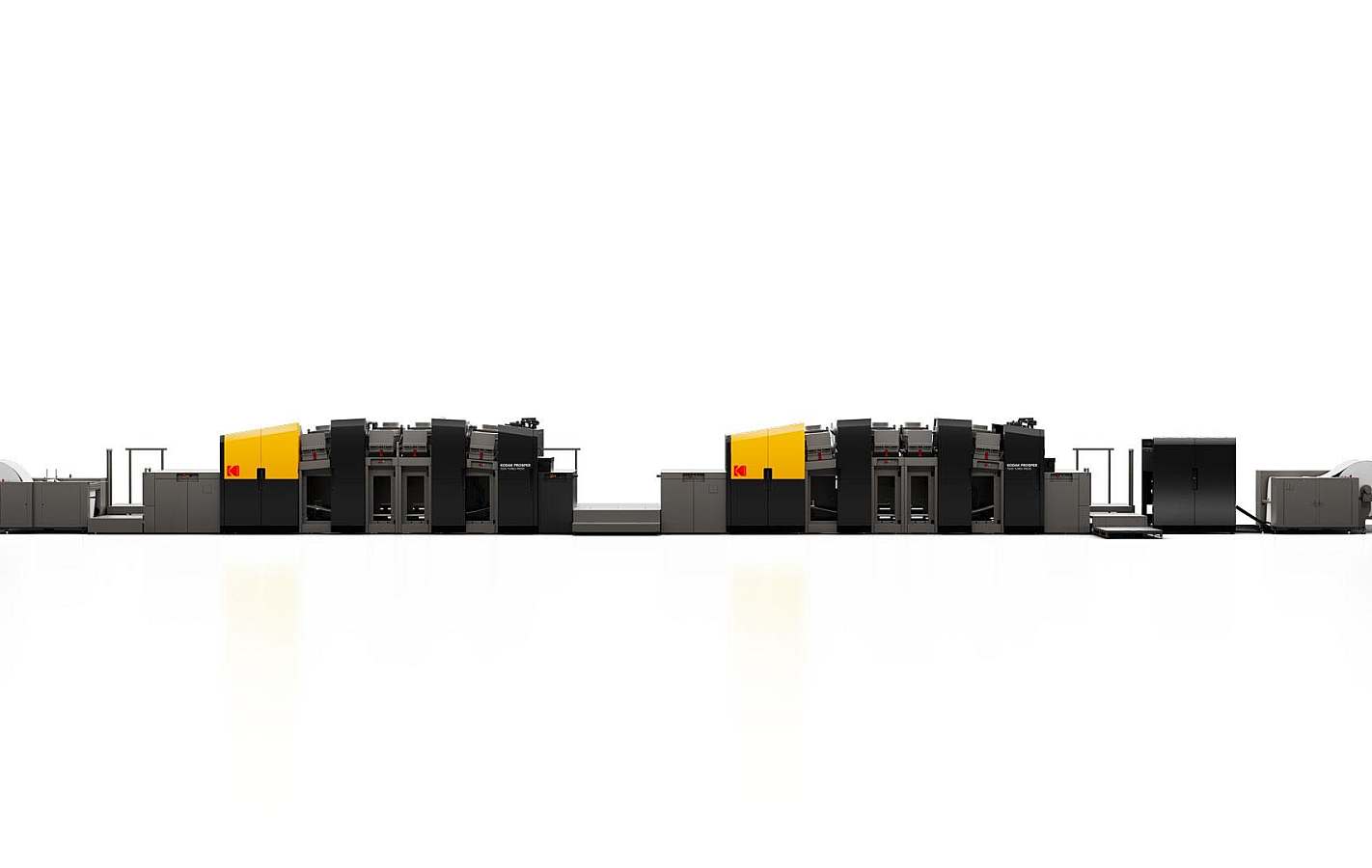

KODAK PROSPER 7000 Turbo Press

The world’s fastest inkjet press

When time is of the essence, the KODAK PROSPER 7000 Turbo Press can handle big jobs, lighting fast. Take on bigger, longer, more ambitious jobs than ever before at the lowest print costs of any inkjet press on the market. Drive higher profits, deliver better turnaround times. Ready to take your print to the next level?

Product Information

Description

Throughput

Up to 410 mpm (1,345 fpm), up to 5,456 A4 ppm4

Image quality

• Approaching 200 lpi at 200 mpm (650 fpm); 133 lpi at 300 mpm (1,000 fpm), 85-100 lpi at 410 mpm (1,345 fpm)

Substrates

• Types: Uncoated free sheet groundwood and matte, glossy and silk coated papers 42-270 gsm (3-12 pt)

• 28# newsprint – 100# cover

• Roll width: 8-25.5 inches (20.3-64.8 cm)

Imaging system

• Technology: KODAK Stream Inkjet Technology

• Ink type: Kodak’s aqueous pigmented process color inks

• Jetting Modules: 4.16”, 48 Jetting Modules within a standard perfecting press

• Imaging width: Up to 62.1 cm (24.45”)

• Variable cutoff: Up to 137.2 cm (54”)

• Duty cycle: 239 million A4 or letter pages/month1

File formats

KODAK 800 Print Manager (Version 5.3 or higher is required) contains:

• KODAK 800 Digital Front End contained in three cabinets with 1 Control Server, 4 Print Process Servers

and 3 DFE Accelerator Server Units

• Press Controller Host PC

– INTEL XEON CPU E3 – 1225 v5 3.3 GHz Processor, 8G RAM, MICROSOFT WINDOWS 10 1607LTSC System

Storage: 500 GB HDD

• DFE Control and Process/Print server contains (at a minimum)

– Dual INTEL XEON CPUs E5 – 2630 v2 2.60 GHz Processors, 16GB RAM, MICROSOFT WINDOWS 10 LTSC

– System Storage: RAID10 – 1TB (4 1TB Enterprise HDD)

– Control Server Job Spool Storage: RAID5 – 6.3 TB (12 1TB Enterprise HDD)

– Process/Print Server Processed Job Storage: RAID0 – 7.4 TB (12 1TB Enterprise HDD)

• DFE Accelerator Server contains (at a minimum):

– Dual INTEL XEON CPUs E5 – 2658 v2 2.60 GHz Processors, 32GB RAM, MICROSOFT WINDOWS 10 LTSC,

System Storage: RAID10 – 1TB (4 1TB Enterprise HDD) System Storage: RAID10 – 1TB (4 1TB Enterprise

HDD)

• Hardware-accelerated image processing technology

• Scalable architecture, for expansion and customer-specific solutions

• Connectivity: Ethernet TCP/IP 1Gbps twisted pair, IPDS (TCP/IP), or JDF/JMF

• One cabinet containing the KODAK PROSPER 800 Press Controller

• Speed: Simultaneous RIP and print capability at up to 410 mpm (1,345 fpm) 5

• JDF/JMF: Job ticket control, enterprise connectivity and workflow automation

• Workflow: Open architecture allows integration into a wide variety of workflows, including KODAK Unified

Workflow Solutions. CIP4 JDF compliant, Remote Client, Remote Job Ticketing, Hot folder file submission

• IPDS connectivity

Dimensions (L x W x H)

• Standard configuration: 28 x 8 x 2 m Physical dimensions of press:

(92 x 26 x 8 feet)2

• L-shaped: 16 x 20 x 2 m (52 x 64 x 8 feet)2

• U-shaped: 15 x 13 x 2 m (50 x 43 x 8 feet)2

Physical dimensions of press:

• Standard configuration: 21 x 5 x 2 m (68 x 16 x 8 feet)

• L-shaped configuration: 13 x 16 x 2 m (44 x 52 x 8 feet)

• U-shaped configuration: 12 x 13 x 2 m (40 x 43 x 8 feet)

Operating environment

• 16° to 30°C (60° to 85°F) @ 10 to 90% RH non-condensing; 30° to 40°C 85 (° to 104°F) @ 10 to 60% RH

noncondensing; Altitude above sea level: 1,830 meters (6,000 feet) max.

Power

• Electrical voltage: 3-Phase 50-60Hz and 208-230 50-60h

• Consumption during operation at 200 mpm (650 fpm): 34.2 Kw (idle), 377.8 Kw (uncoated papers), 401.9 Kw (glossy and matte coated papers)3

• Consumption during operation at 300 mpm (1,000 fpm): 34.2 Kw (idle), 402.8 Kw (uncoated papers), 442.6 Kw (matte coated papers)3

Consumables

• Jetting modules: KODAK PROSPER Press Jetting Modules

• Inks: KODAK PROSPER Press Pigment Cyan, Magenta, Yellow and Black Inks; Indirect food contact Inks

• Other fluids: KODAK PROSPER Press Storage Solution and Replenisher Fluid

• Ink supply: 208-liter drums (55 gal.)

Solutions

• Job submission: KODAK INSITE Prepress Portal System

• Creation and organization: KODAK INSITE Creative Workflow System and KODAK INSITE Asset Library

• Production management: KODAK PRINERGY Workflow v5.1 or higher

• Proofing: KODAK MATCHPRINT Inkjet Proofing System and KODAK MATCHPRINT Virtual Technology

• Asset management: KODAK Data Management Solutions

• Color management: KODAK COLORFLOW Software

• Qualified finishing solutions: Available from Kodak authorized providers

Optional accessories

• KODAK PROSPER Press Jetting Module Recovery Station

• KODAK Color Toolkit Plus Station and training6

• Auto Splicer (provided by Kodak partner)

• Pre- or Post-Coating Station (provided by Kodak partner)

• Kodak’s Ink Estimator Software