Horizon StitchLiner MARK III – Saddlestitching System

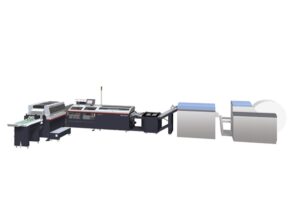

The Standard Horizon StitchLiner Mark III Saddlestitching System features increased productivity up to 6,000* booklets per hour. The system can produce a wider range of applications, including landscape-size booklets, 12” by 12” calendars, and pocket booklets down to 4.5” by 3.5”. The StitchLiner Mark III offers fully automated set-up, including stitching head settings, with no manual adjustments required for book thickness at the trimmer, delivering higher quality booklets with greater efficiency, even for variable stitch length and variable page count booklets.

* Stated speed specifications WILL be reduced when using a HOF-400 feeder. Projected throughput specifications, based on customer applications, can be provided upon request.

Advantages at a glance

- Fully-automated Settings – All necessary adjustments which includes length and balance are automated.

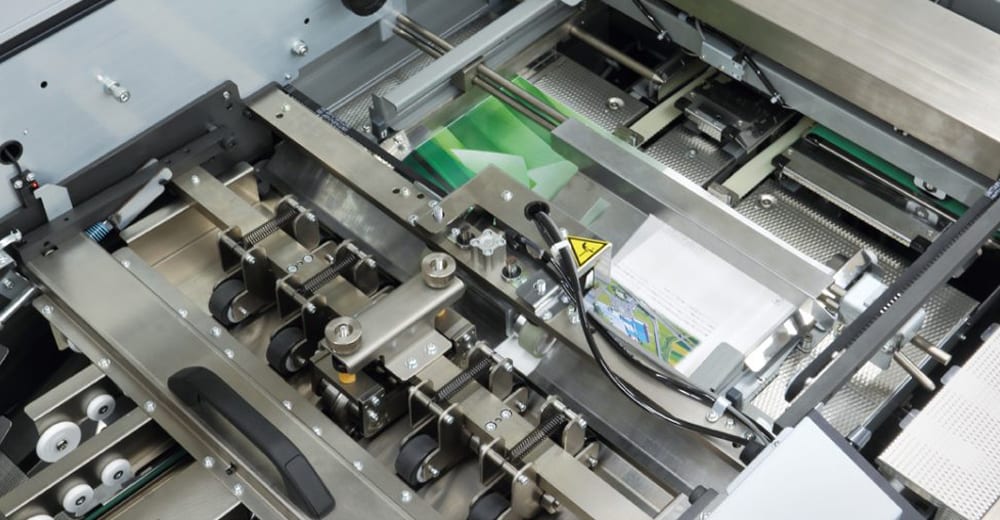

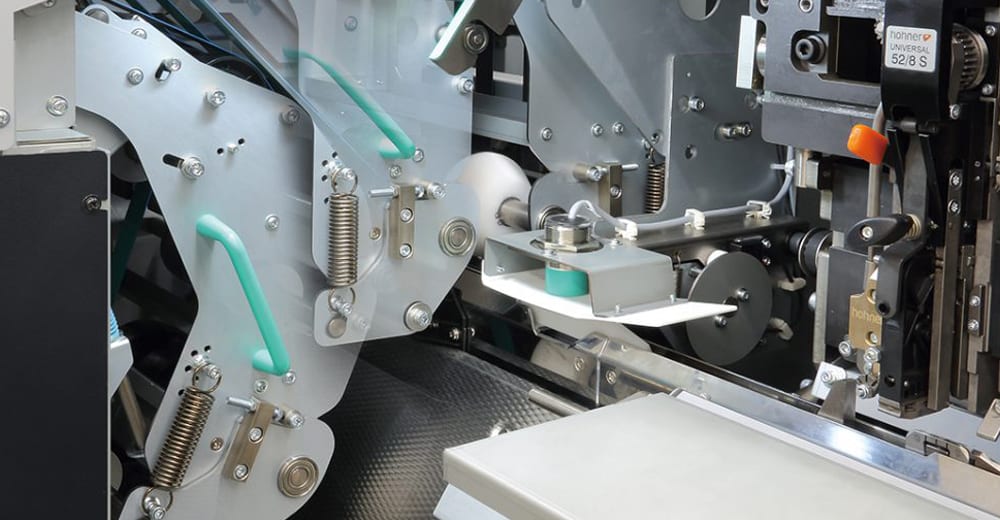

- Higher Quality Booklet – Newly designed systems for sheet transport and jogging, scoring and folding, stitch and fold monitoring, and positive jog register at the trimmer.

- Variable Thickness Production – True end-to-end automation for variable thickness production, variable stitch length and balance adjustment combined with variable thickness transport adjustment through the trimmer.

- A4 Landscape Stitching – Expanded format size to meet A4 landscape large format calendar production. Higher productivity is achieved on a wider range of formats, including A4 landscape at over 5,000 per hour.

Product Information

Description

| Sheet Size Maximum: | 14″ W x 20″ L (356 mm (W) x 508 mm (L)) |

| Sheet Size Minimum: | 5.5″ W x 7.6″ L (140 mm (W) x 194 mm (L)) |

| Sheet Weight Range: | Normal: 52.3 to 350 gsm / Coated: 73.3 to 350 gsm |

| Booklet Size Maximum (before trim): | 14″ x 10″ (356 mm x 254 mm) |

| Booklet Size Minimum (before trim): | 5.5″ x 3.8″ (140 mm x 97 mm) |

| Trim Width: | 0.08″ to 1″ (2 mm to 25.4 mm) |

| Production Speed: | 6,000* booklets/hr maximum |

* Stated speed specifications WILL be reduced when using a HOF-400 feeder. Projected throughput specifications, based on customer applications, can be provided upon request.