Horizon iCE Binder BQ-300 – Compact On-Demand Binding

High Quality

Enhanced automation and new features of the BQ-300 allow even non-skilled operators to produce high quality books. The new template feature helps automate various binder adjustments so that anyone can achieve efficient book-of-one production. Templates are created beforehand depending on style or substrate preferences and can be chosen at any time depending on job requirements.

Easy Operation & Maintenance

The newly designed 15” control panel (“Horizon XUI”) and increased mechanical automation help improve productivity by shortening setup time and eliminating touchpoints. New pullout delivery stacker allows for easier handling of bound books, while the front covers provide easy access to the inside for maintenance and cleaning.

High Productivity

BQ-300 achieves up to 500 cycles per hour and achieves job changeover times that are up to 50% shorter than previous models. Additionally, enhanced variable thickness automation allows the BQ-300 to achieve efficient production even for short-run jobs.

System Extension Capabilities

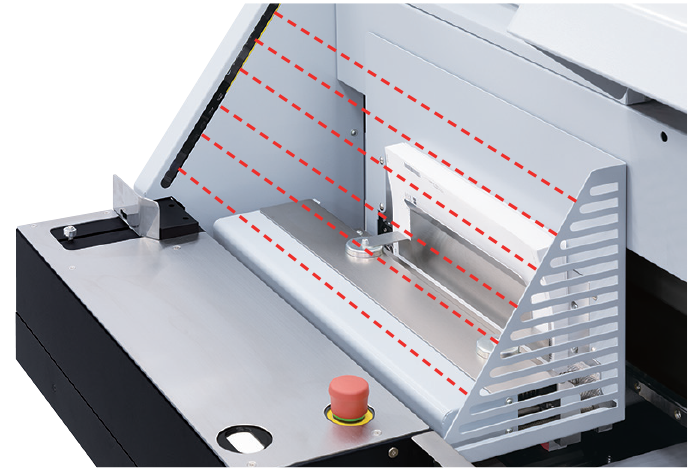

BQ-300 can be configured inline with a trimmer or robotic arm. The system can be enhanced with automated workflow from upstream to post-press with iCE LiNK. iCE LiNK is Horizon’s cloud-based postpress management system that allows users to monitor production and machine status in real time, or automate their workflow by integrating finishing with their MIS and prepress.

Advantages at a glance

- User-friendly and highly accurate binder

- Quick set-up

- High-speed binding

- Accurate binding

- Variable binding compatibility

- Optional pXnet bindery control system available

Product Information

Description

| Binding Type | Binding with milling, Binding without milling, and Pad binding |

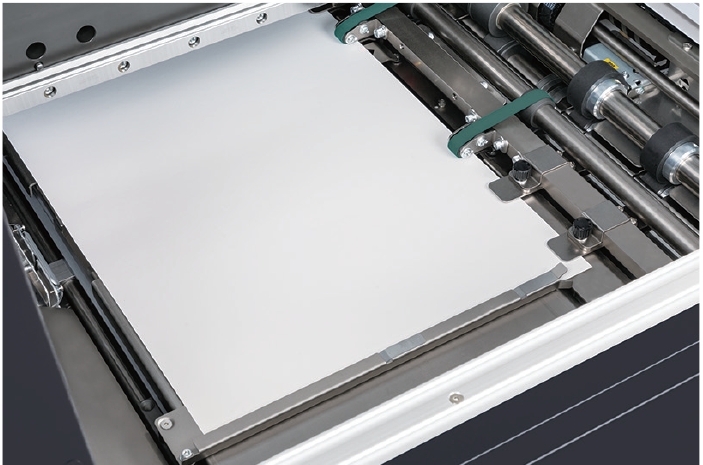

| Book Block Size: | Spine Length × Fore-edge Length Max. 320 × 320 mm or 12.59” × 12.59” Min. 135 × 105 mm or 5.32” × 4.14” A4 / B5 / A5 / B6 / A6 |

| Book Thickness: | 1 to 51 mm or 0.04″ to 2.00” |

| Cover Size Maximum: | Max. 320 × 660 mm or 12.59” × 25.98” (up to 350 mm or 13.77” forwards from the clamp face) (up to 310 mm or 12.20” backwards from the clamp face) |

| Cover Size Minimum: | Min. 135 x 225 mm or 5.32″ x 8.86″ mm (up to 115 mm or 4.53” forwards from the clamp face) (up to 110 mm or 4.34” backwards from the clamp face) |

| Cover Weight Range: | Normal Paper 81.4 to 302.4 gsm Coated Paper 104.7 to 348.9 gsm |

| Cover Stack Height: | Max. 70 mm or 2.75” |

| Glue Temperature: | 120 to 190 degrees Celsius or 248 to 374 degrees Fahrenheit |

| Milling Depth: | Max. 4 mm or 0.157″ (Adjustable in increments of 0.5 mm or 0.02″.) |

| Production Speed: | Max. 500 cycles per hour. |

| Voltage/Frequency: | 3-phase 200 to 220 V, 50 or 60 Hz 3-phase 208 V, 50 or 60 Hz |

| Machine Dimensions: | 2,330** (W) x 910 (D) x 1,530 (H) mm or 91.74” (W) x 35.83” (D) x 60.24” (H) (This dimension is measured including the parts protruding from the cover.) |

| Machine Weight: | Only the Main Body: 970 kg or 2,138.49 lb |