THE NEW 8-UP+ RMGT 970

ASAP System: Assisting your potential, maximizing your throughput

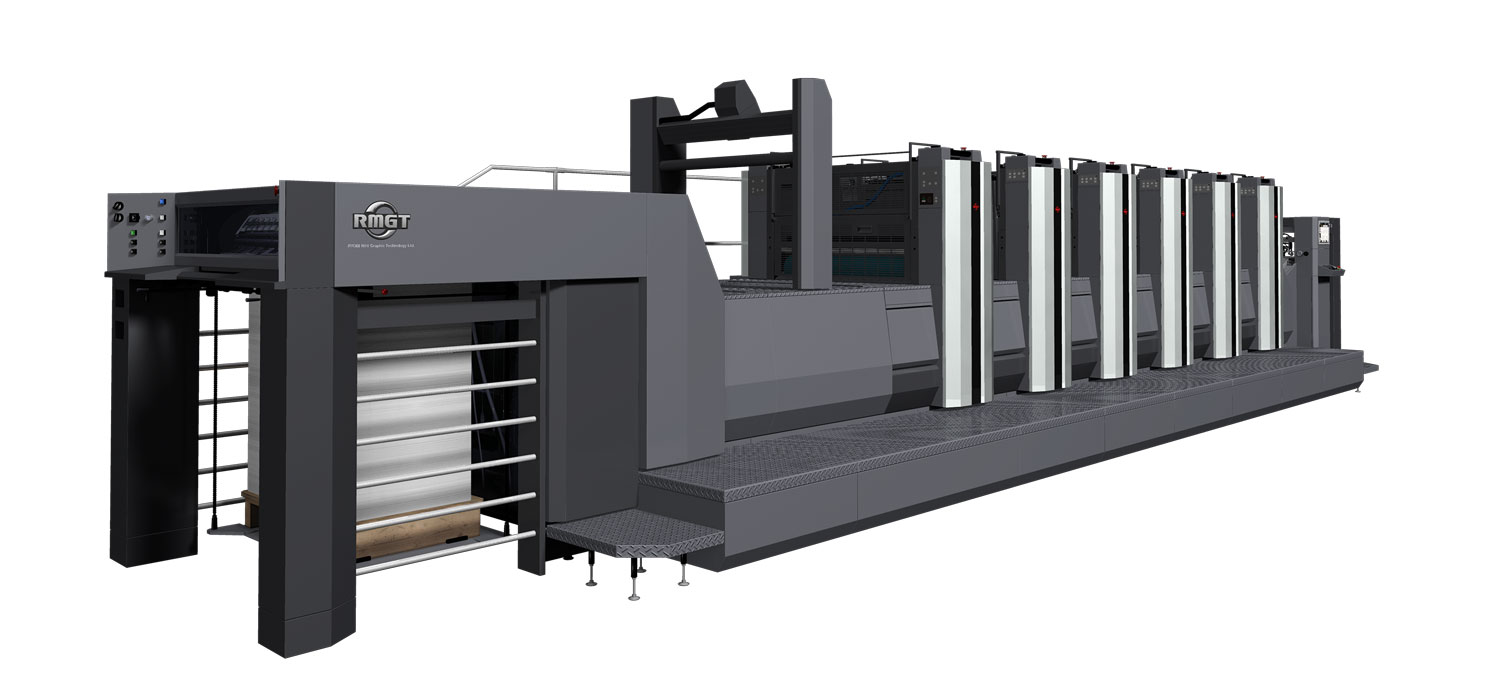

RMGT Launches New 8-UP+ Size 970 Series Offset Press

View the Virtual Demo running Live below!

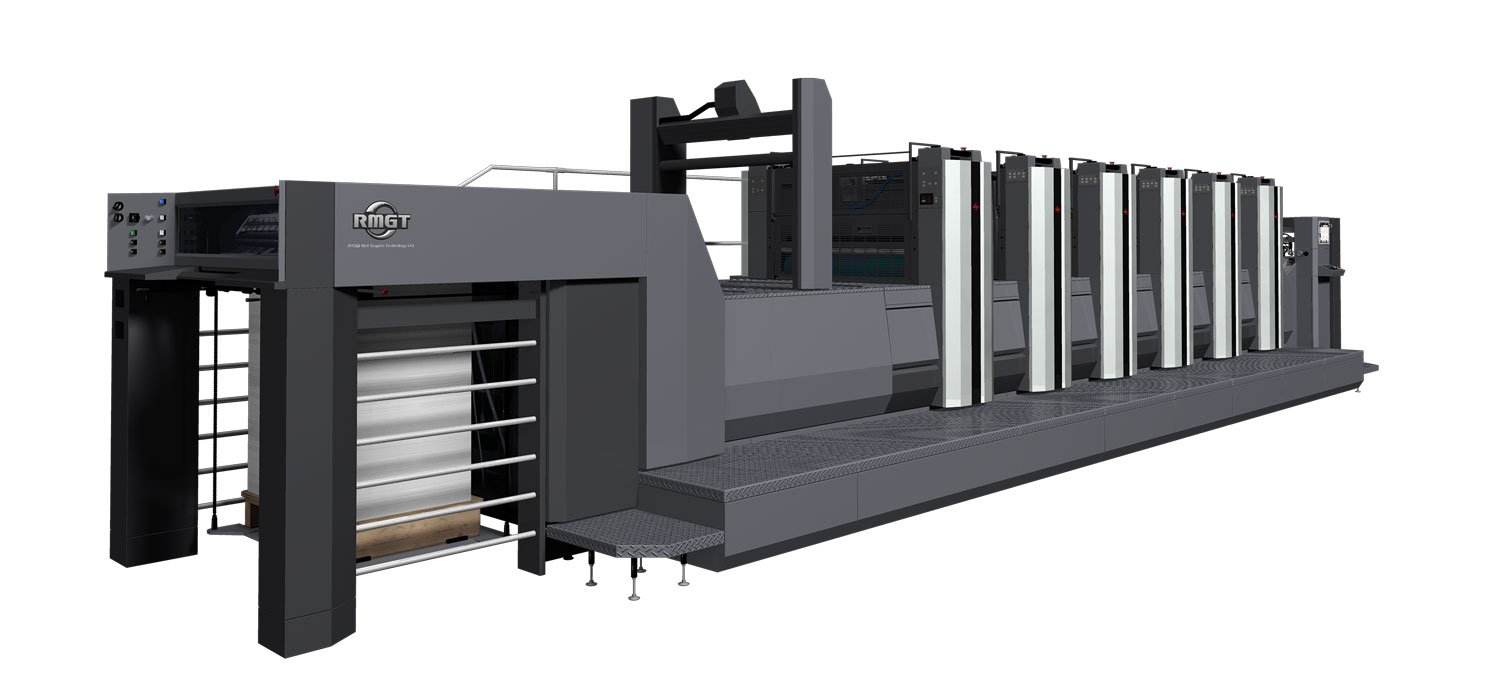

The release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format.

The ASAP System

Smart Insta.Color technology has proven itself with fast makeready times for many years, and the release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format.

With ASAP the pressman touches one button and the entire printing process—from ink and paper presetting, blanket and impression cleaning, and plate changing through verification of test printing, register adjustment, ink density adjustment, and full sheet inspection are all autonomously processed by the ASAP system without even pulling a sheet.

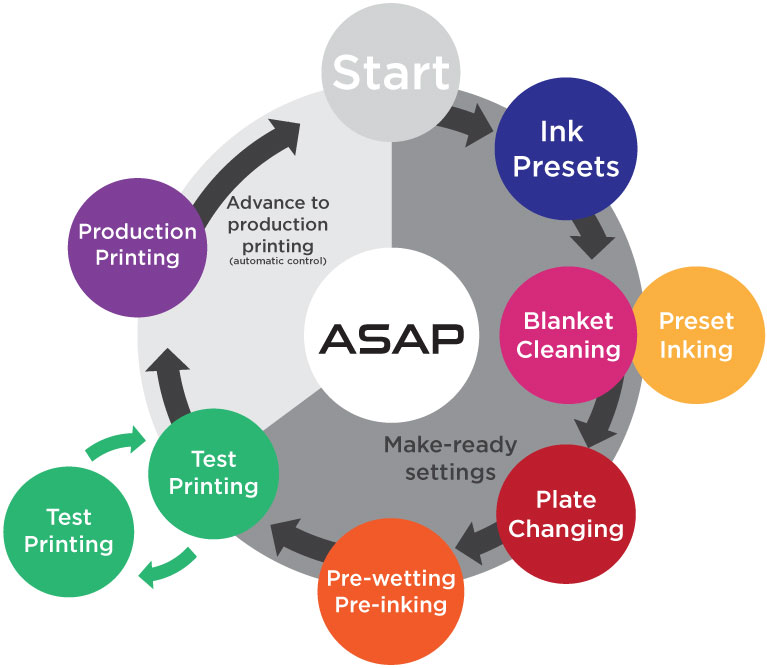

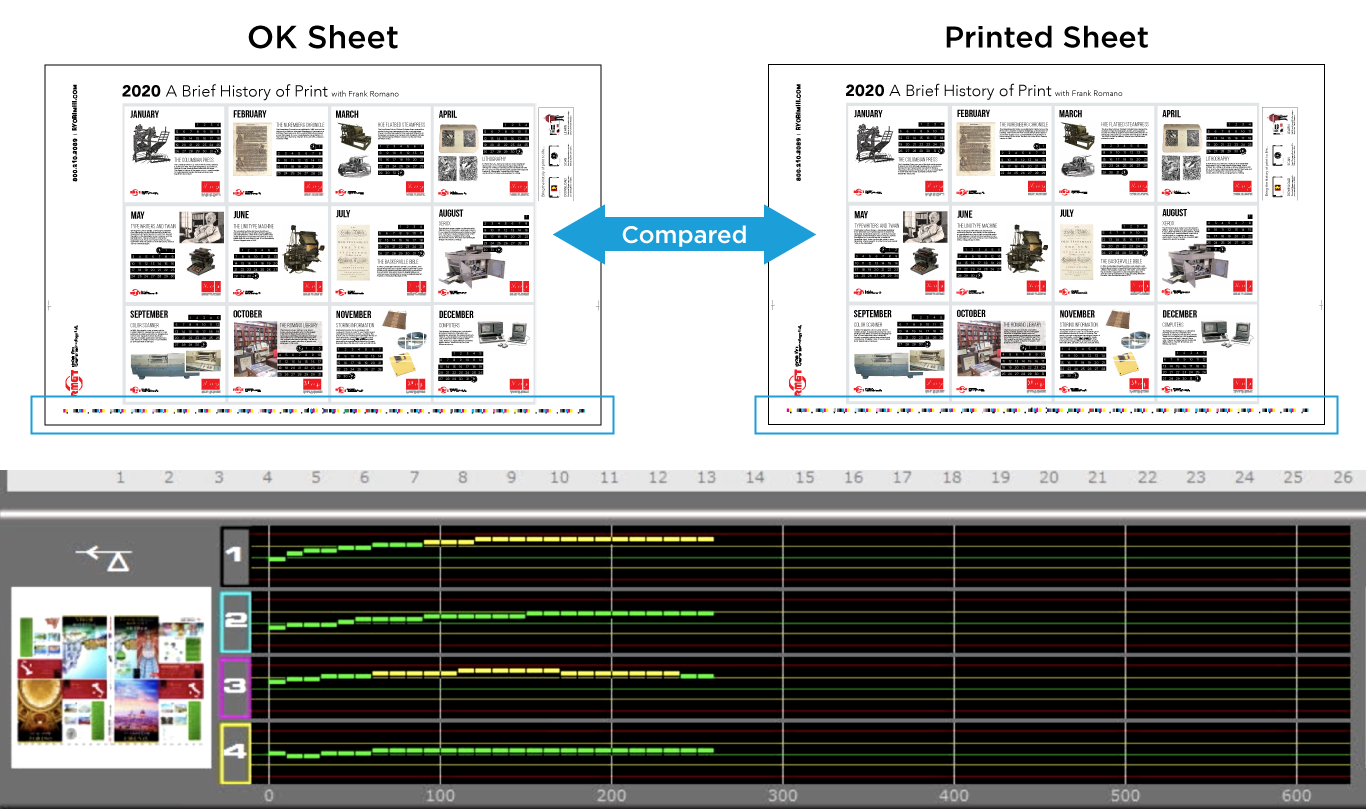

PQS-D+I Quality Inspection Function

PQS-D+C Printing Density Tracking Function

PQS-D+I Quality Inspection Function

Shorter make-ready time

The New RMGT 970 Offers three plate changing options:

- SPC - Semi-Automatic Plate Changing System (Standard)

- FPC - Fully Automatic Plate Changing System (Optional)

- Smart FPC - Fully-Automatic Simultaneous Plate Changing System (Optional)

All plate changing systems are equipped with a Benderless Plate Clamp that eliminates the plate bending process.

PQS-D+R Automatic Register Adjustment Function

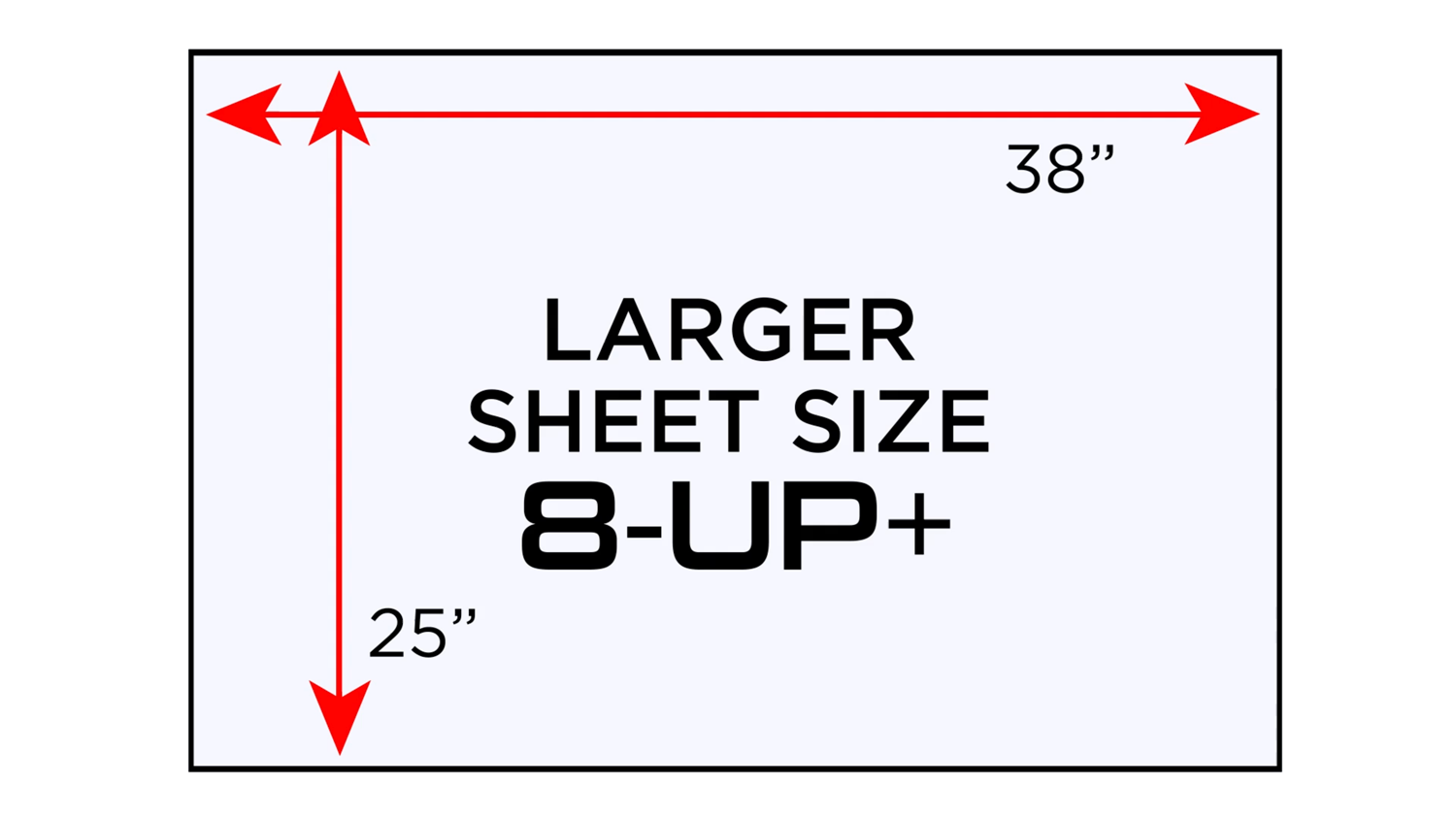

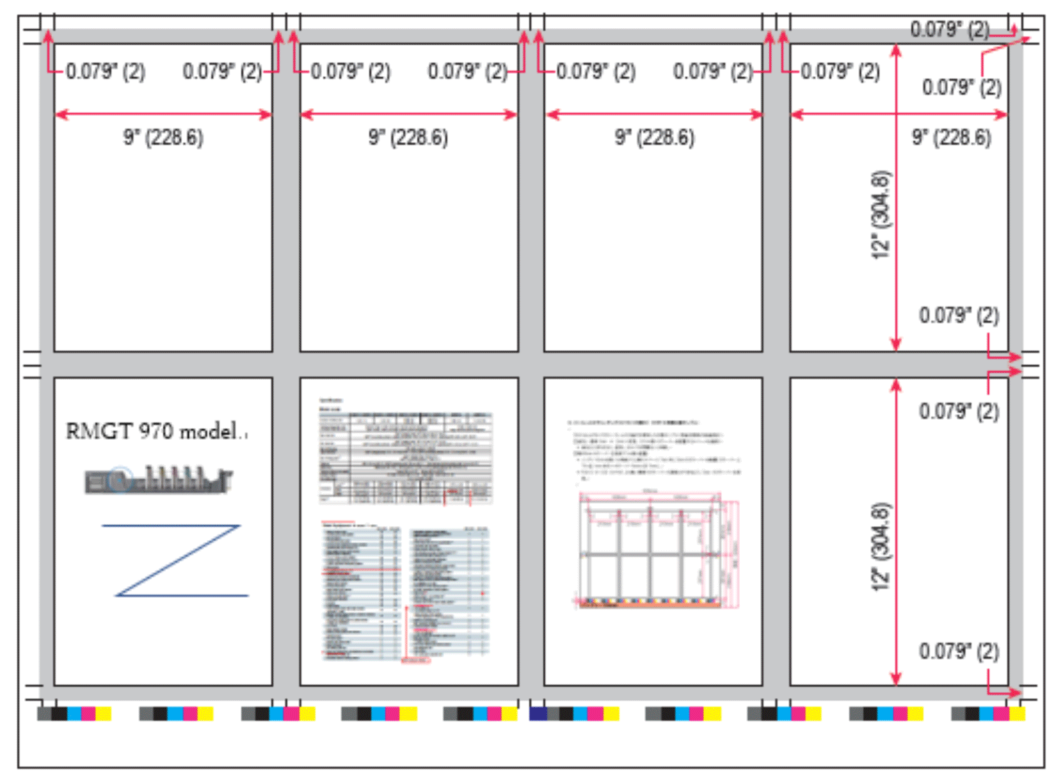

8-UP+ size format

The New 8-UP+ Format

Straight from the paper house to the presses

Single Pressman Operation with ASAP & Speed Productivity Boost

The ability to staff a highly automated RMGT 8-UP press with a single pressman was important for profitability and flexibility prior to March of 2020, but as the printing industry recovers from the economic results of COVID-19 reducing per shift staffing costs will bring greater viability to pressrooms who take the 9 Series approach to manufacturing.

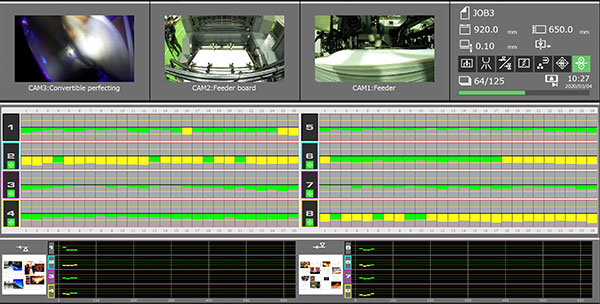

Automatic monitoring of printing status and printing quality

A 55-inch large screen display for the operation stand allows easy monitoring of printing quality and operating status. Real-time viewing of sheet transfer by press-mounted video cameras is available on the live-view monitor at the press operation stand.

The information display features a monitoring function to show image data, job progress, print density measurement results, and the operating conditions of safety devices.

* Optional

Density Measurement monitor & Live view Monitors

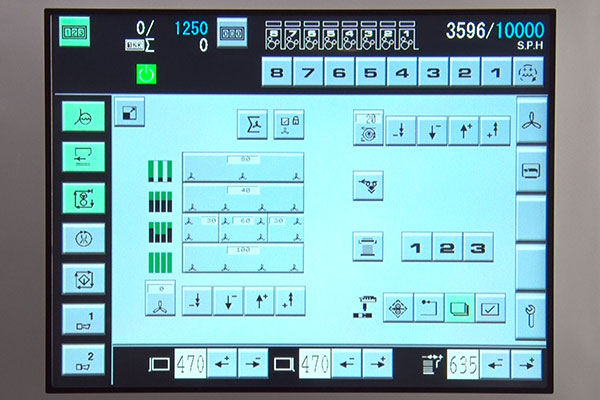

New Streamlined User InterfaceFeeder and delivery section touchscreen panels

Various feeder section operations, settings and checks can be performed via a touchscreen panel, including starting a print run, the counter settings, feeder air presetting*, and feed timing checker. Delivery section settings such as adjustment of the back guide and side guide as well as adjustment of the delivery fan volume are also performed via a touchscreen panel, greatly simplifying delivery section tasks. Both operation panels are equipped with error description displays and other monitoring functions to assist the press operator *Optional |

Delivery fan volume adjustment screen

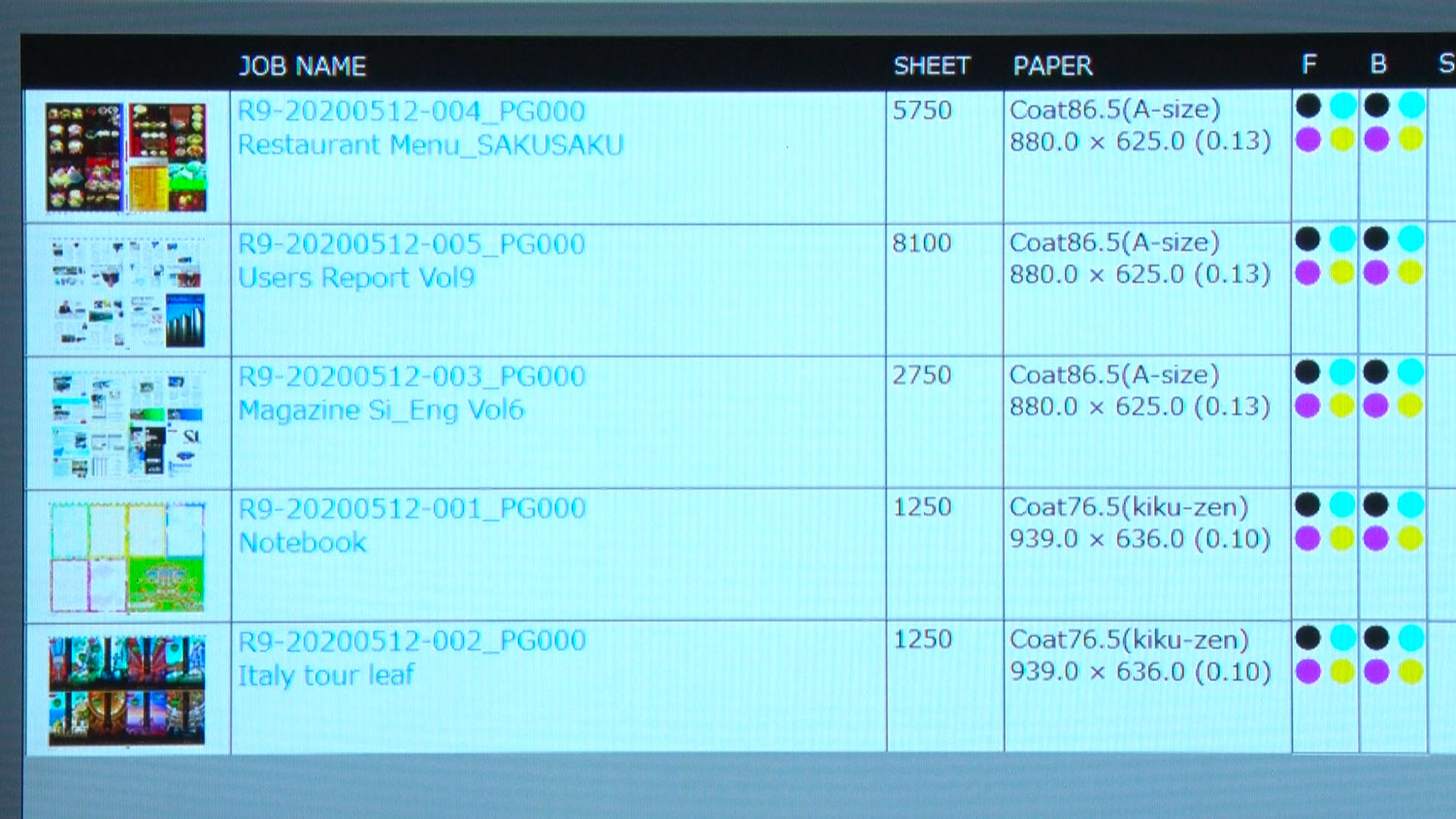

Automatically Registered Printing Queue

Digital Workflow

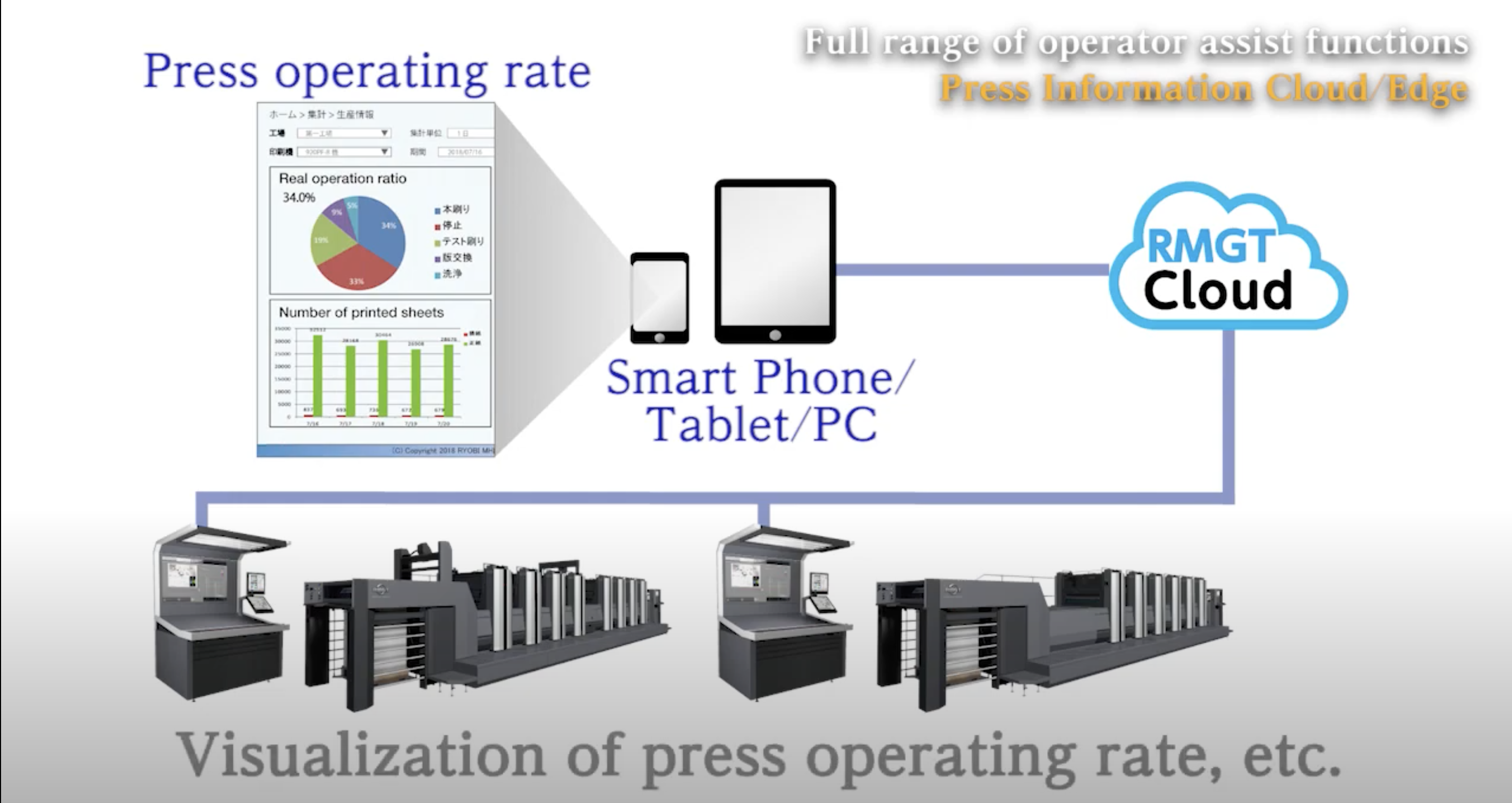

Press Information Cloud Edge*

|

MIS connection software {CIP4-JDF)*

MIS connection software connects a CIP4-JDF compatible MIS (Management Information System) and PCS-G printing control system for real-time printing process management. |

Print Job Manager*

The optional Print Job Manager press operation control system connects compatible presses via a network to manage the production schedule and transmit printing job data. It also collects data on press operating status in real time and automatically generates production analysis data.

PPC Server (PPC Server III)*

This server converts image area ratio data generated by CIP3/CIP4-PPF and CIP4-JDFenabled prepress systems and provides data on ink key opening volume.

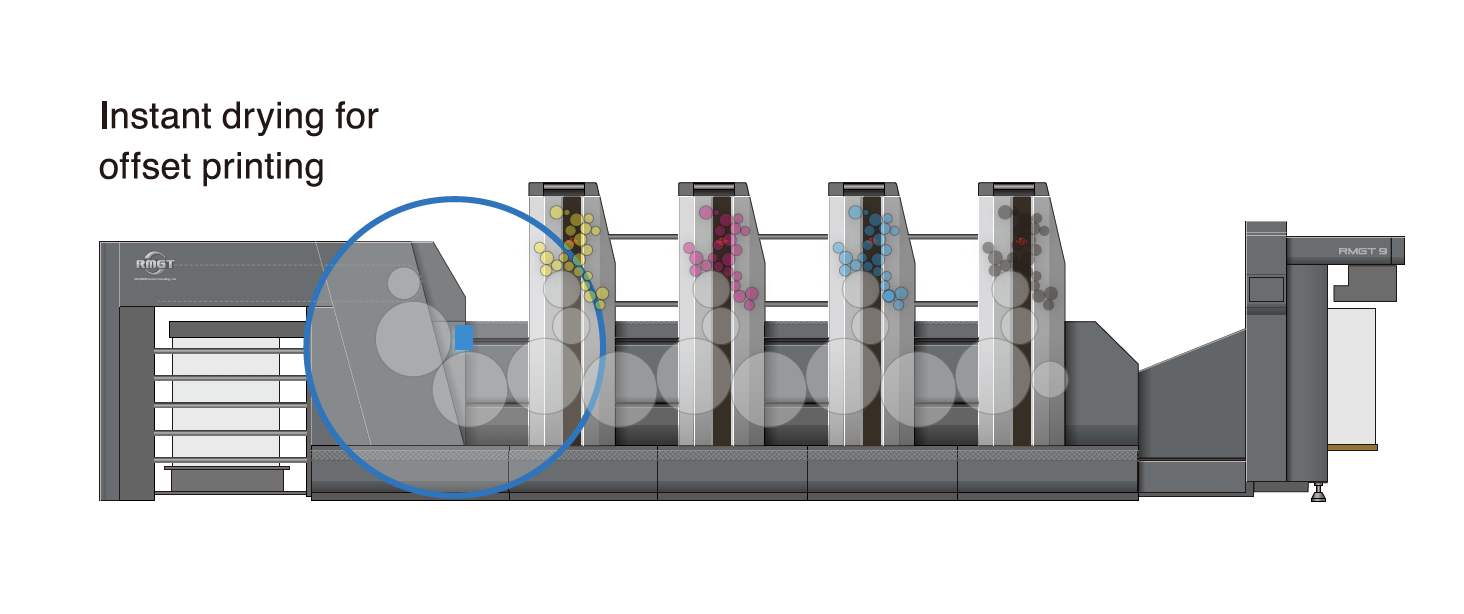

LED-UV Curing System*

Improves Productivity with

High Environmental Performance

*option

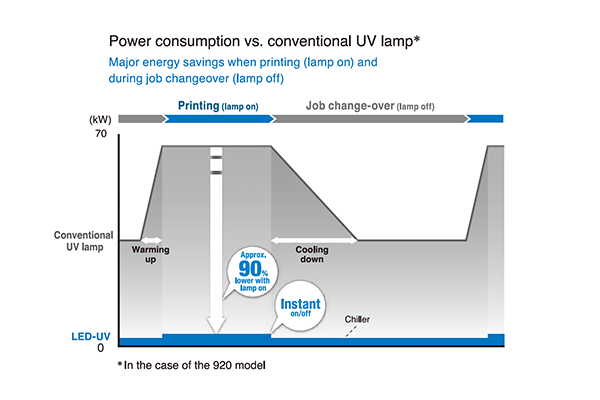

Features of LED-UV curing system

Power consumption of the LED-UV curing system is only 10 percent* of that of conventional UV lamp system. In addition, the instant on and off of LED-UV lighting eliminates the need for substantial standby power.

*In the case of the 920 model

A conventional UV lamp system's light source lasts approximately 1,000 to 3,000 hours*, but the LED-UV curing system's light source has a long life of approximately 15,000 hours. Moreover, a conventional UV lamp system remains lit in standby mode during makeready work, shortening its life, while the LED-UV curing system remains completely off so light source life is unaffected.

* Life cycle of the UV lamp depends on such conditions as on and off frequency.

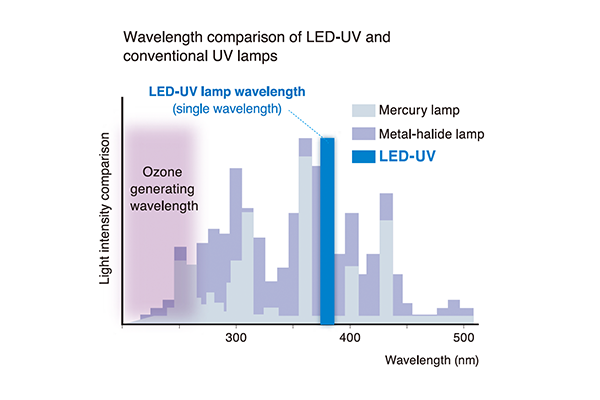

The LED-UV operates within a UV wavelength where no ozone is generated, eliminating the ozone odor peculiar to UV printing.

The minimal heat generated during curing reduces thermal impact on the printed sheets and eliminates the need for exhaust ducting.

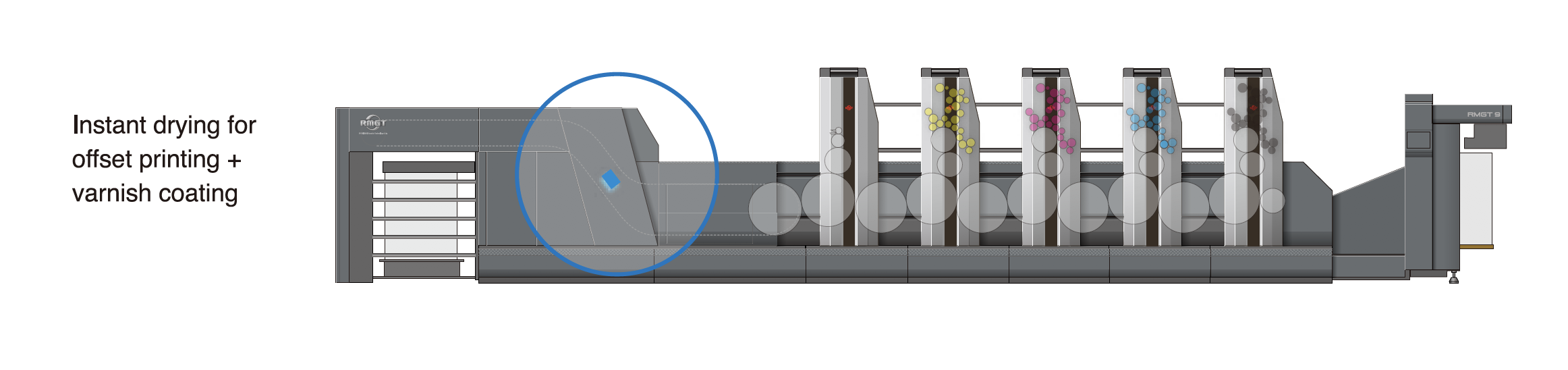

Varnish and special substrates for high-value-added printing*

* Drying performance may vary depending on printing conditions such as paper, ink , varnish, drying unit and printing speed and etc.

RMGT 970 ST-4 Straight Press

RMGT 970PF-8

Convertible Perfector

RMGT 970ST-5 Straight Press

(with varnish coating unit)