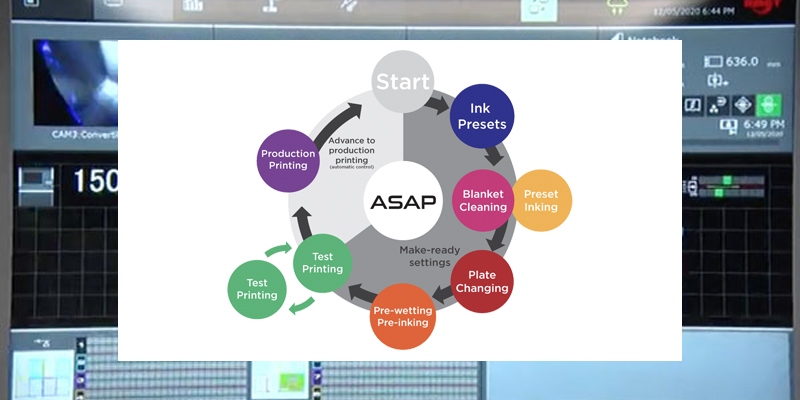

The ASAP System

Automated Smart Assist Printing Increases Press Operating Rates for Continuous Printing of Short-run Work

Smart Insta.Color technology has proven itself with fast makeready times for many years, and the release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format.

With Automated Smart Assist Printing (ASAP), the pressman touches one button and the entire printing process—from ink and paper presetting, blanket and impression cleaning, plate changing through verification of test printing, register adjustment, ink density adjustment, and full sheet inspection are all autonomously processed by the ASAP system without even pulling a sheet.

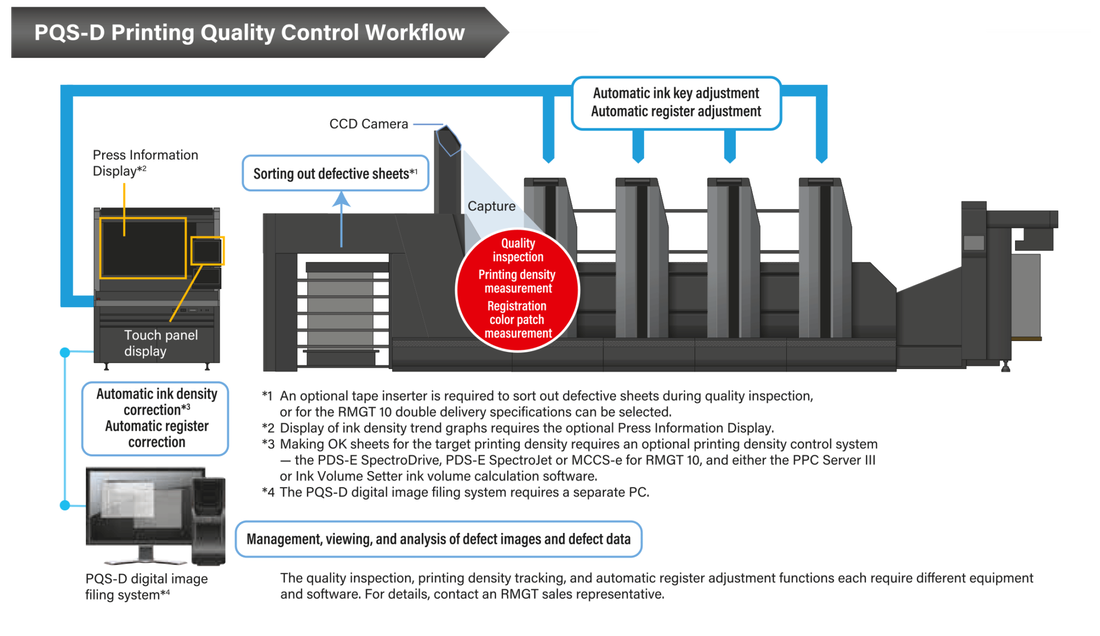

PQS-D (I+C+R) Print Quality Control System

Quality inspection function + Printing density function + Automatic register adjustment function

From commercial printing and very short run digital-like runs to packaging printing, RMGT’s PQS-D system uses a high-precision in-press CCD camera to inspect each printed sheet with superior reliability. The PQS-D eliminates the need to pull out sample sheets during the run and defective sheets are automatically sorted out, enhancing quality assurance and further automating printing.

The multifunction PQS-D system lets you perform 3 key functions in-press with a single camera (per side of sheet). The scanning process can be archived to provide back up quality control data to a printer’s end user.

The beauty of the PQS-D (I+R+C) system is that the three functions detailed below are ALL processed at the same time, dramatically compressing the makeready time and allowing an RMGT pressman to focus on higher production.

Need more information?

The release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8-UP+ press format.

PQS-D+I Quality Inspection Function

With PQS-D+I the CCD camera scans every sheet and sheets with defects such as hickeys, marking, water drops or blurred characters are automatically detected. They are then sorted out using either an optional tape inserter or an optional dot matrix inkjet numbering approach. Defects as small as .5 mm X .5 mm will be automatically detected and sorted out by the PQS-D I system.

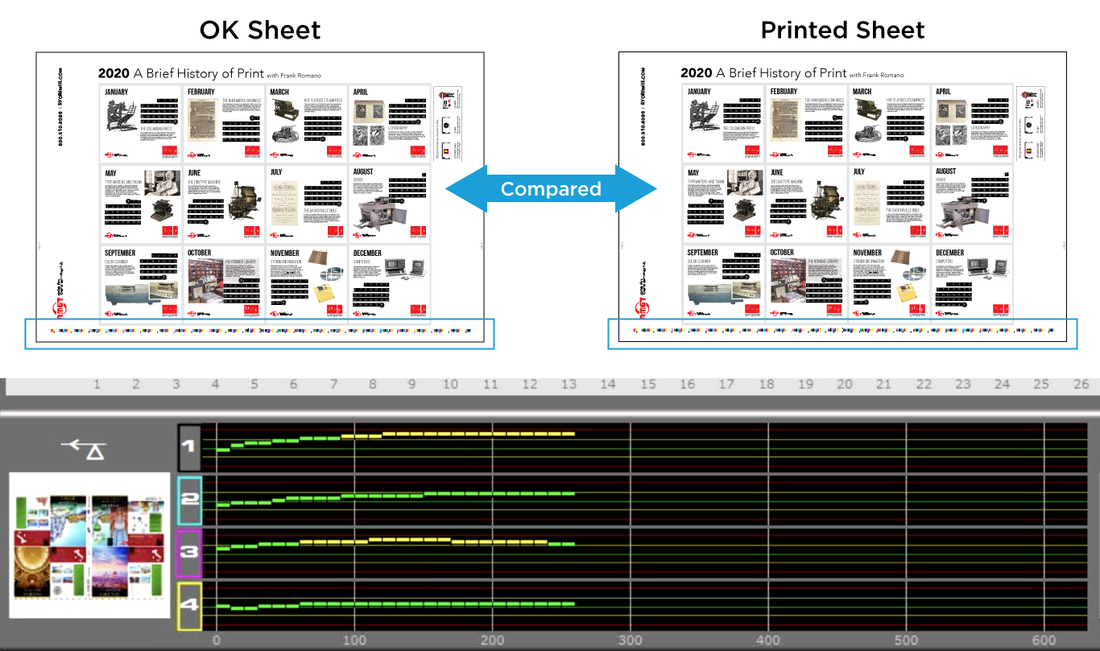

PQS-D+C Printing Density Tracking Function

The PQS-D+C captures images of the color bar for comparison with the target density. The ink keys are then automatically controlled using a closed loop approach to eliminate any difference in density, automatically achieving consistent printing density. Any sheets that fall outside of the preset quality control range are then sorted out using either an optional tape inserter or an optional dot matrix inkjet numbering approach.

Shorter Make-ready Time

The New RMGT 970 Offers three plate changing options:

- SPC - Semi-Automatic Plate Changing System (Standard)

- FPC - Fully Automatic Plate Changing System (Optional)

- Smart FPC - Fully-Automatic Simultaneous Plate Changing System (Optional)

All plate changing systems are equipped with a Benderless Plate Clamp that eliminates the plate bending process.

PQS-D+R Automatic Register Adjustment FunctionUsing the PQS-D+R module captures images of the registration marks and registration is automatically adjusted to within industry tolerance. The need to pull sheets is eliminated using the PQS-D system

|