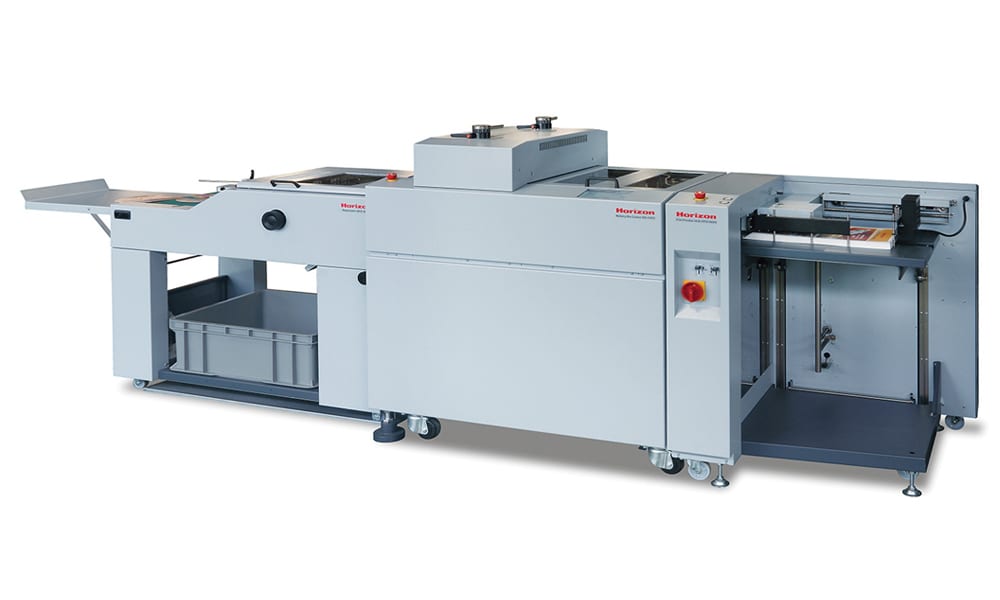

Horizon RD-4055DMC – Die-cutter

The Horizon RD-4055DMC Rotary Die Cutter with dual magnetic cylinders is designed to simultaneously die-cut and crease/score short-run product from both sides of the sheet. In addition to die cutting and creasing/ scoring, it can also perforate, slit, hole punch and round corner in one process for digital and offset printed sheets. The RD-4055DMC enables the operator to run male and female dies simultaneously for clean, sharp creases without cracking or slitting. This system features easy change-over and simple operation. A “Repeat Register” function allows multiple-up applications from a single-up die to minimize costs. The RD-4055DMC is ideal for greeting/note cards, playing cards, coasters, door hangers, coupons and tickets, boxes and packaging, stickers (pressure sensitive, gum back, static), bottle and merchandise labels, pocket folders, and unique mailers. The RD-4055DMC handles complex creasing patterns and light packaging applications with ease.

Advantages At a Glance

- Rotary Die-cut System – Rotary die-cutter designed to meet the growing demand for short-run products. The rotary die-cutters are light and compact compared to normal die-cutters.

- Flexible Substrate – Die-cut and kiss-cut in various substrates for digital and offset printed sheets.

- One Pass Processing – Feeding, die-cutting and separating are achieved in one pass.

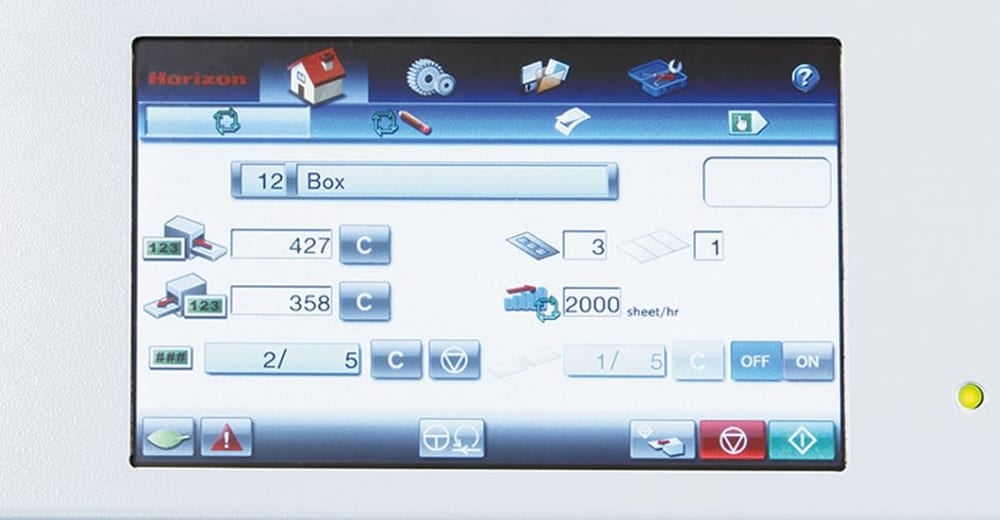

- Save the Cost of Making Die – Uniquely designed servo motor controlled “repeat register” feature allows multiple-up applications from single-up die to minimize die cost.

- Simple and Easy Operation – Reduces costly labor steps and increases productivity with easy set-up and operation versus steel rule or mechanical dies.

Product Information

![]() Brochure

Brochure

![]() Case Study

Case Study

Product Video 1

Product Video 1

Product Video 2

Product Video 2

Product Video 3

Product Video 3

Product Video 4

Product Video 4

Description

| Sheet Feeding System: | Vacuum Belt-Feed |

| Sheet Size: (before processing) |

Max: 15.74” W x 21.65” L Min: 7.88” W x 10.83” L |

| Finished Sheet Size: (with Separator) |

Max: 14.8” W x 20.8” L Min: 1.97” W x 3.15” L |

| Finished Sheet Size: (without separator, with nicks) |

Max: 15.1” W x 20.8” L Min: Depending on die shape |

| Processes Material: | Normal paper, coated paper, cardboard |

| Material Thickness: | 127.9 to 400 gsm |

| Feeder Pile Height: | 19.68” |

| Production Speed: | Up to 6,000 cycles per hour |