Foliant Mercury 530 NG 4×4 – Industrial Double-sided Laminating Machine

The Foliant Mercury 530 NG 4×4 is a Double-sided Industrial Laminating Machine, constructed for nonstop, heavy-duty digital and offset printed sheets for lamination. It is equipped with a Foliant integrated suction feeder and high-speed bump separator. Several options are available for the Foliant Mercury 530 NG 4×4: pallet stacker, non-sticky rollers or Foliant foiler. Due to its high-pressure system, format and performance, the machine is suitable for all jobs – all kinds of digitally printed sheets and high volumes of offset printed sheets 14: x 20″ for lamination. The machine’s maximum speed is up to 88 feet/minute single-sided lamination and 82 feet/minute in double-sided lamination, while performance is 2,300/2,100 sheets per hour of 19.7 x 27.8 in portrait (white paper 200 gsm).

Advantages at a Glance

- Easy operation

- Equipped with a rising back pile separation stream feeder with a Foliant suction feed head

- Single-sided and double-sided thermal industrial laminator

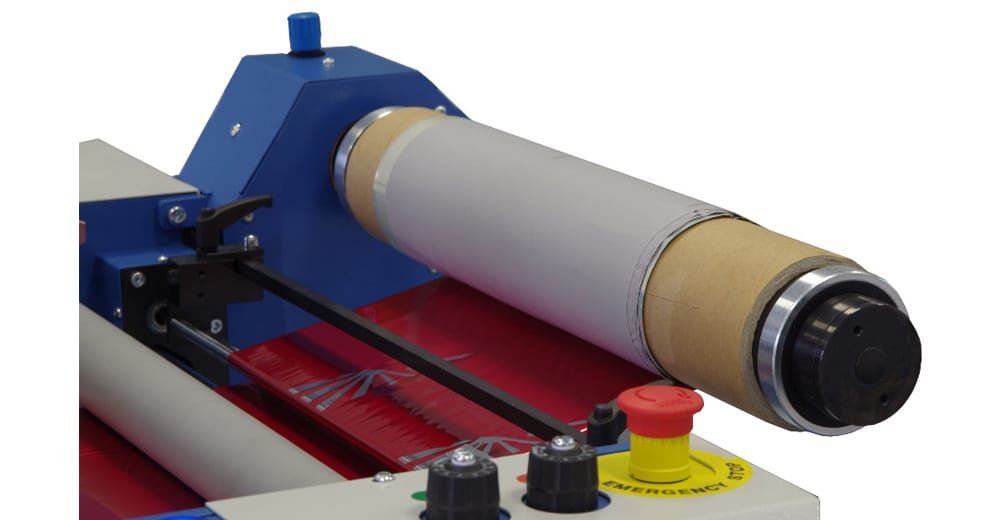

- Film is mounted on a quick-change shaft with a film tension control breaker

- Film holder unit is equipped with a trim slitter and perforation wheel

- Pressure is pneumatically adjustable

- De-curl blade for offset printed sheets

- De-curl roller for digitally printed sheets

- OMRON programmable logic controller for easy automation

- Optional jogger*, pallet stacker*, non-sticky pressure roller (up to 2x), film loader/manipulator, film micro adjustment air shaft (up to 2x) and Foliant Foiler

*Important: The machine must be operated with either a Jogger or a Reception Unit.

Product Information

Description

| Maximum Speed (Single/Double): | 88/82 feet/minute |

| Feeding: | Automatic |

| Feeding System: | Heidelberg suction feed head |

| Feeder Load Capacity: | 21.2” (54 cm) |

| Overlaps: | Automatic, PLC Control |

| Overlap Accuracy: | ± 0.08″ (2 mm) |

| Separation: | Automatic, Bump Rollers |

| Paper Weight: | 115 – 600 gsm |

| Main Rollers Pressure System: | Pneumatic |

| External Compressor: | 150 l / Minute, 6 – 8 Bar |

| Minimum Sheet Size: | 12.5” W x 9.8” L (32 cm x 25 cm) |

| Maximum Sheet Size: | 20.8” W x 29.5” L (53 cm x 75 cm) |

| Maximum Performance (Single/Double): | 2,300/2,100 19.7″ x 27.8″ SPH |

| Warm Up Time: | 8 minutes |

| XL Module (Sheets Up to 39.3″): | Optional |

| Floor Space with Jogger | 47.2″ W x 122″ L (120 cm x 310 cm) |

| Jogger 530*: | Optional |

| Integrated Motorized Pallet Stacker: | Optional |

| Pallet Stacker Capacity: | 27.5” (70 cm) |

| Film Loader/Manipulator: | Optional |

| Film Micro Adjustment Air Shaft: | Optional (Up to 2x) |

| Non-sticky Pressure Roller: | Optional (Up to 2x) |

| Foliant Foiler: | Optional |

*Important: The machine must be operated with either a Jogger or a Reception Unit.